Dental Implants

All Metè products are manufactured according to the procedure and quality guidelines defined by the European legislation for medical and dental devices production.

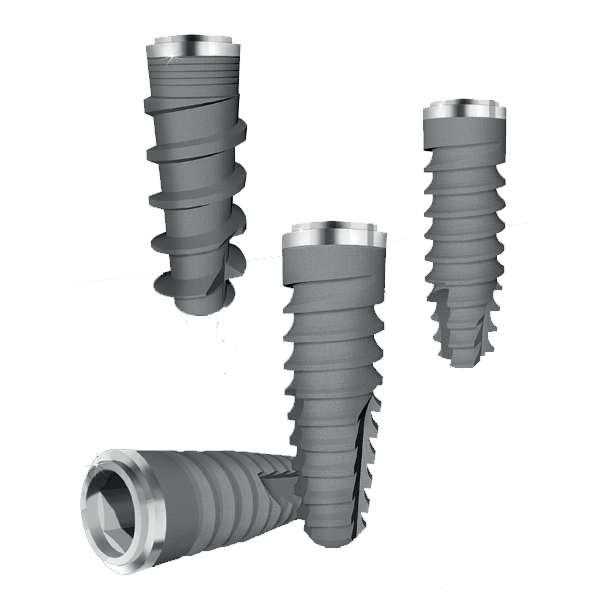

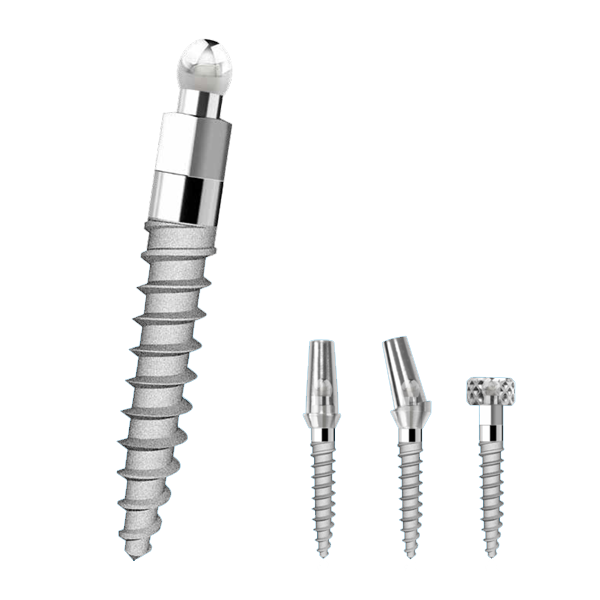

The implant design is characterised with a tapered body and a particularly aggressive coil, designed to provide ideal primary stability in all types of bone.

Surface Treatment “Sandblasting and acid-etching” helps to obtain a micro-roughness which enhances the speed of the osseointegration process.

Excellent decontamination is performed by using an Argon Plasma reactor in a cleanroom.

- Self-tapping dental implant

- Internal hexagon connection

- Single platform for all diameters

- Platform switching

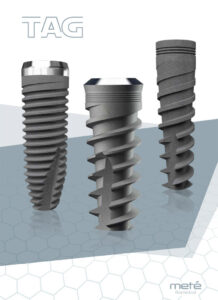

TAG LINE – TAG Straight

The internal hexagonal connection, with conical implant-prosthetic support, guarantees greater stability by reducing micro-movements between fixture and abutment.

- Self-tapping cylindrical implant

- Internal hex connection

- One platform for all diameters

- SAE surface treatment for high osseointegration

TAG LINE – TAG 3.0

EXAGON LINE

Exagon implant design is characterised by external hexagon connection which has excellent results in “all on four” technique realization and bar system.

Fixture shows cylindrical shape with self-tapping coil.

More tapered design is also available to provide better primary stability by thight surgical preparation

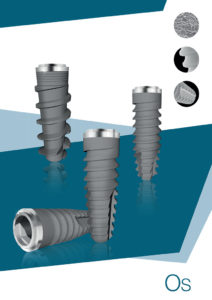

OS LINE

OS implant line is equipped with conical and straight fixture design, maintaining same connection.

This dual design aims to help the primary stabilization in all bone density.

All implants are characterized by apical millings which improve penetration and favor an optimal clot flow.

MINI OS LINE

COMPATIBLE ABUTMENTS